Building a roller furler

Written in Turkish by Habib Atinc.

Translated by Zeki Berk and Gilad Barak

Note about the translation – this is a non professional translation, done by one person who knows Turkish, but not much of boats and sailing, and one person who knows boats and sailing but knows no Turkish. Also, an attempt was made to keep the spirit of the original.

Hello,

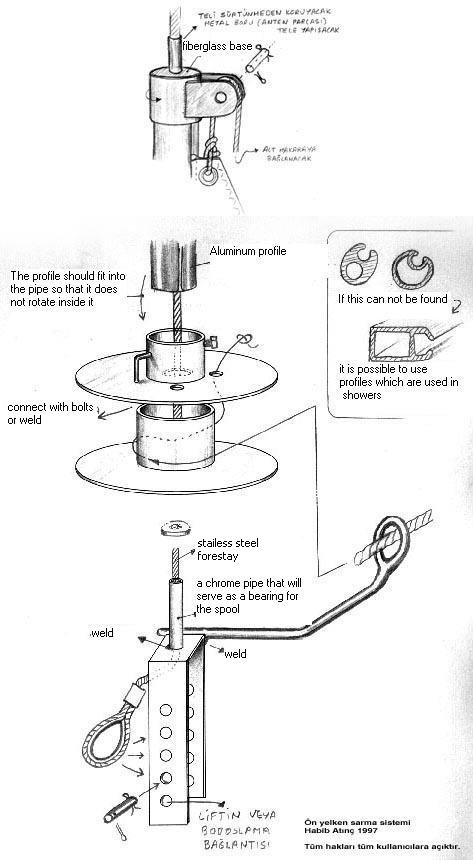

I promised to explain how to build a roller. Only now I found time for that. I will provide the general information and the rest can be seen in the detailed drawing which I made (click for hand drawing or for a CAD schematic).

Of course there is a simple solution. Buy it. Think of it…. You are gently stroking the shiny parts which came out of the box. The manual which has “Plastimo” over it is already next to you. The wallet is a bit lighter, but this would definitely fit your boat. Go ahead, shut down the computer and find your way to the nearest chandlery store. I will tell you frankly, this is the simplest way that will bring you to the perfect solutions. Sometimes I envy you. Come on, lets find us a brand name!

If you are still reading, I’ll go on. Maybe after reading you will still go and buy a ready made solution, and keep yourself out of a lot of trouble, but my logic and point of view are different. The decision is yours……

The main material of the system is stainless steel. You will be able to find almost completely ready parts at junk yards.

The drum

This drum is made of two circular plates and two pipes. One of the pipes is inserted between the plates, to form a drum on which the pulling line is wound. The larger its diameter the less effort you will need to pull it, but you will have to pull more line. Remember the formula: work = force x distance. The second pipe, which is fitted on top of the drum should match the diameter of the aluminum profile which holds the sail. It should also be very tightly attached to the aluminum profile, since this is the point which carries most of the load. Since my profile is elliptic, I found an elliptic pipe and prevented the possibility of the profile turning inside the pipe. If the profile is round there is a tightening problem, you will think of a solution for this problem. The drawing also shows the hole for the forestay etc. You can do it differently, just remember that the larger the hole the less friction and chafe for the forestay. Remember also this: the weight that the roller adds to the mast may affect the boat’s stability. A simple calculation in my case showed a 1:7 ratio meaning 1 kilo added to the center of gravity of the mast requires 7 kilos added to the ballast. It just happened that I wanted some addition to my ballast and when I did it the problem was solved.

The fork

This part, which is the lowest, is made by bending a flat bar and drilling holes as shown in the drawing. The norsmen or the eyelet of the forestay are attached with a pin running through the holes. The lowest hole is used to connect the sternpost. I connected it to the end of the sprit and the mast forestay was connected to the sternpost. If you want attach a turnbuckle to this part but make sure to lock it so it does not open by itself.

At the top of the fork weld a stainless steel pipe which will serve as an axis for the drum and will prevent the edges of the drum holes from chafing the forestay. The fairlead for the furling line should be close to the drum, but should not touch it – weld it accordingly to the fork.

Aluminum profile

This is the hardest part to obtain. I searched all the aluminum manufacturers. They have it in their catalogs, but not in stock. They manufacture to order (250 kilograms). The section of this profile contains a tunnel for the wire in the sail luff and a hole in its center for the forestay. You will not find this profile everywhere. It may be found at sail eqiupment stores, but it is expensive. Not worthwhile for this roller. Just as I was about to buy a profile with corners like those used for baths and showers, I saw in the marina a thrown roller profile. Although it seemed abandoned, I searched for the owner and sent him a message. The owner said he did throw it away because it was bent and that it would not do me any good. I insisted, and with the help of a mediator and a bottle of raki (a turkish, anise based liquor) I got the part. I straightened it, cleaned it and used it.

The top

This is the part which contains the pulley which pulls the sail upwards. As can be seen in the drawing, it is a pipe made of stainless steel, which contains a part made of phenolic fiber. Since my forestay is galvanized wire, in order to prevent friction at that place I covered it at that point with a plastic sleeve taken from an antena which was glued with epoxy based cement. Before I forget let me say that if you cover the forestay throughout its whole length with a plastic sleeve, the profile will not wear against the inside.

As to assembling the roller, which looks flimsy, think well ahead of the assembly sequence. Just like threading beads on a string – thread all the parts and at the end the norsmen.

If you are reading this, I assume you will know the operation principle. The main principle: when unrolling the sail the furling line loads into the spool by itself. When pulling the furling line the sail is wrapped around the profile.

You can improve the roller. You can add some useful features such as a shield for the drum, a ball bearing etc. Also, there are models which work with the wire which is in the sail, without the profile. I do not like these. Last year, in the boat of my friend Nejat, did we suffer until we were able to roll the sail. This is also why there is one cellphone still out of receiving range – it can not receive at the depth of 20 meters.

Cost

Parts bought at junk yards don’t cost much. If you will find the aluminum profile, like me, you will not pay for it. I know you have on your boat parts like bolts, nuts and sleeves. If you need welding gear lend it from a friend – I can be that friend. Now for the forestay – this is the most expensive part. Realy, don’t you have a forestay already? Use it and get it over with. Here, a free roller. Just a joke…. set aside 3-5 cents for this business.

Good luck.